Digital Maturity Index in Aerospace Machining : What it really means for Indian Manufacturers?

by Saravana Kumar

In recent years, terms like Digital Transformation, Industry 4.0, and Smart Factory have become commonplace across industrial sectors. For aerospace component manufacturers - especially those based in India - these buzzwords often trigger curiosity, urgency, or even confusion. While large multinationals may already be deep into their digital journeys, many small and mid-sized enterprises (MSMEs) are still trying to figure out where they stand and how to move forward.

This is where the concept of Digital Maturity Index (DMI) becomes incredibly relevant. Think of it as a report card of your factory's digital evolution - a structured framework that helps manufacturers understand their current digital capabilities and plan their next steps strategically.

Understanding Digital Maturity in Aerospace

Digital maturity refers to how extensively a manufacturing organization has adopted digital tools, technologies, and mindsets across its operations. In an industry like aerospace, where precision, traceability, and compliance are non-negotiable, digital maturity isn't just a competitive edge - it's a necessity.

Whether it's maintaining tight tolerances, meeting rigorous documentation standards, or ensuring repeatability in production, having the right digital backbone directly influences performance. Delays, inconsistencies, or missing records can lead to rejected parts, increased security, or even grounded aircraft - outcomes no aerospace supplier can afford.

Thus, assessing and improving digital maturity is vital for sustainable growth, customer satisfaction, and regulatory compliance.

Why it matters more in Aerospace Machining?

Aerospace component machining stands apart from other forms of manufacturing. Here, every detail matters - be it the surface finish of a titanium bracket or the thermal treatment records of a landing gear component. Traditional, paper-based workflows can't keep up with such high demands.

A well-planned digital journey enables:

1. Accurate and Real-Time Traceability

Digital records ensure that every operation - right from raw material sourcing to final inspection - is traceable with minimal manual intervention.

2. Improved Quality Assurance

Integrated quality systems help detect deviations early, reduce rework, and maintain consistent part quality.

3. Faster Decision Making

When production data flows in real time, teams can respond quicker to issues, optimize processes, and make better-informed decisions.

4. Efficient Compliance Management

With digital Certificate of Conformance (CoCs), automated approvals, and audit trails, regulatory compliance becomes seamless rather than stressful.

5. Higher Customer Trust

OEMs and Tier 1 suppliers value transparency and reliability. A digitally mature shop instills greater confidence and is more likely to win repeat contracts.

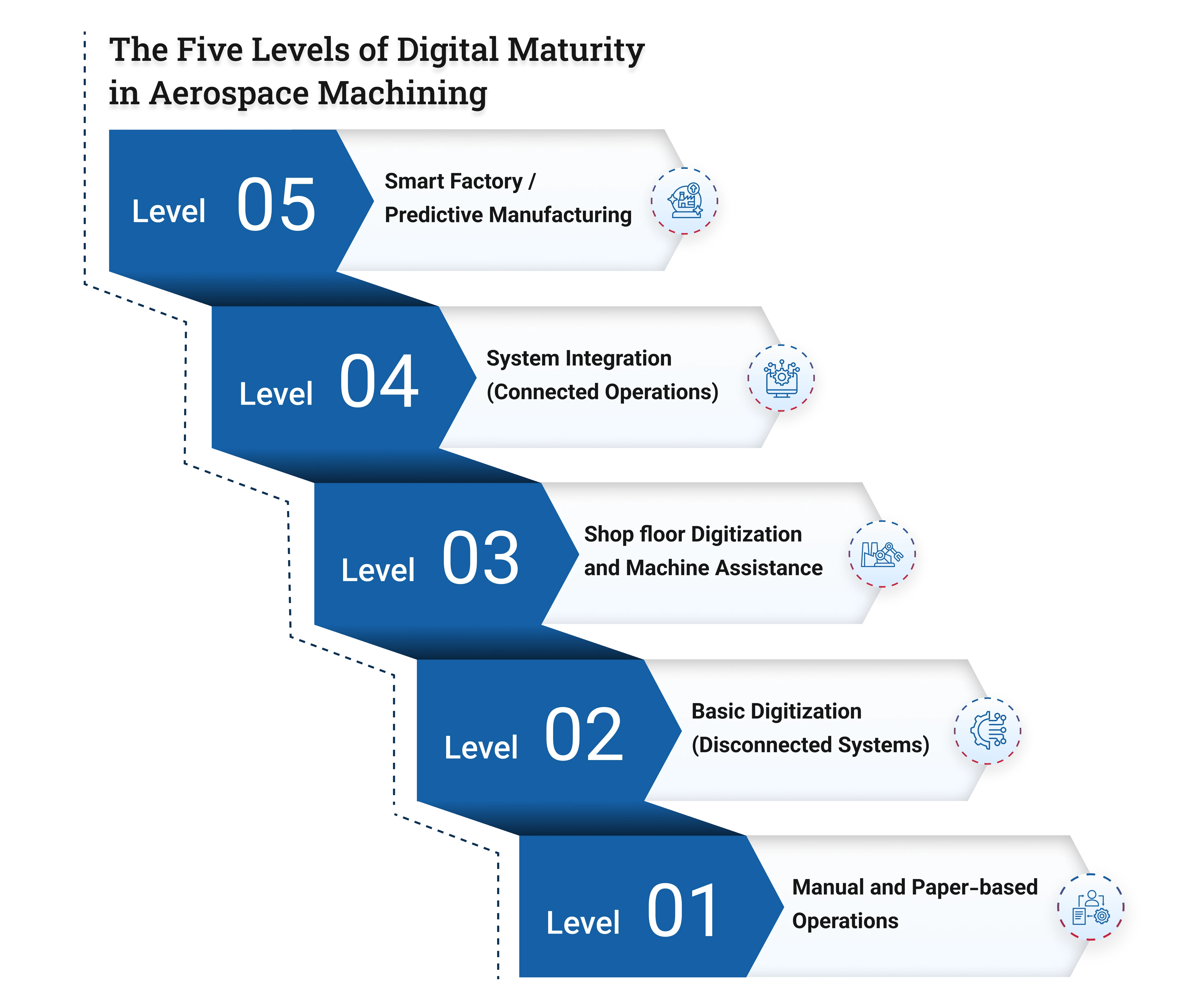

The Five Levels of Digital Maturity in Aerospace Machining

To make digital transformation more approachable, the Digital Maturity index can be broken down into five distinct levels. Each level represents a stage of evolution, with clearly defined characteristics, benefits, and challenges.

Level 1 - Manual and Paper-based Operations

At this foundational level, the entire manufacturing workflow is driven by manual processes. Paper checklists, handwritten logs, and physical filling systems dominate the floor. While this setup may function, it is prone to:

- Frequent errors and omissions

- Delayed reporting and approvals

- Poor visibility into production status

- High effort in preparing for audits

This stage is common among small or newly formed MSMEs that are entering the aerospace supply chain and are yet to make digital investments.

Level 2 - Basic Digitization (Disconnected Systems)

In Level 2, manufacturers take their first steps toward digitization, primarily focusing on replacing paper with digital documents. While this is a step forward, the systems remain siloed and unintegrated.

- Excel spreadsheets replace paper logs

- Communication moves to email

- Records are stored in folders, not file cabinets

- Machines remain unconnected

Despite reducing paper clutter, inefficiencies persist because data entry is still manual, error-prone, and time-consuming. Decision-making remains reactive rather than proactive.

Level 3 - Shopfloor Digitization and Machine Assistance

This is where automation starts making a meaningful impact on daily operations. Machines begin to share data, and shop floor visibility improves.

- Production data such as part count and cycle time is captured automatically

- Operators interact with digital terminals or tablets

- Dashboards offer visual representation of production metrics

- Alerts notify supervisors about exceptions or downtimes

Although individual systems (like machine data monitoring or maintenance logs) are functional, they're not yet integrated into a larger, unified ecosystem. Still, this level marks a significant jump in productivity and quality responsiveness.

Level 4 - System Integration (Connected Operations)

Reaching Level 4 means transitioning from individual digital tools to a connected, data-driven factory. Systems that were once isolated now begin to "talk" to each other.

- ERP, MES, and QMS Platforms are integrated

- CoC documents are generated automatically

- Real-time quality and production monitoring becomes standard

- Digital approvals streamline workflows and reduce delays

- Deviations are flagged instantly, triggering corrective actions

This level paves the way for optimized operations. It significantly reduces human dependency in routine tasks and makes compliance reporting a breeze.

Level 5 - Smart Factory / Predictive Manufacturing

At the highest stage of digital maturity, factories don't just monitor - they predict and optimize.

- AI-driven algorithms forecast potential defects before they occur.

- Predictive maintenance schedules reduce downtime.

- Digital twins simulate changes before implementation.

- Data analytics helps fine-tune processes continuously.

- End-to-end digital traceability ensures instant audit readiness.

Factories at this level are capable of self-learning, adapting to shifts in demand or complexity with agility. Such capabilities are particularly valuable in aerospace, where part variations and compliance expectations can be incredibly diverse.

Where do Indian Aerospace MSMEs stand today?

A significant number of Indian Aerospace MSMEs are currently navigating between levels 2 and 3. While some have embraced basic digitization, others have begun experimenting with shopfloor automation and data monitoring.

However, challenges persist:

- Cost Barriers - High-quality digital systems are often seen as expensive, especially for small-scale manufacturers.

- Resistance to Change - Teams accustomed to manual processes can be hesitant to adopt new tools.

- Skills Gap - Without trained personnel, even the best tools can fail to deliver ROI.

- Lack of Strategic Vision - Without a long-term roadmap, digital efforts can become disjointed or stall completely.

Despite these hurdles, growing demand from global OEMs, regulatory requirements, and export opportunities are pushing Indian MSMEs to climb the digital maturity ladder.

How to Progress Up the Maturity Curve

Aerospace manufacturers aiming to improve their digital maturity should adopt a structured approach:

1. Start with a Digital Audit

Assess where your operations currently stand. Identify pain points, gaps, and strengths.

2. Prioritize High-impact Use Cases

Focus on areas like production visibility, CoC automation, or quality control - places where digital tools can create immediate value.

3. Choose Scalable Solutions

Avoid isolated, short-term fixes. Invest in platforms that can grow with your needs.

4. Train Your Workforce

Upskilling teams is non-negotiable. Digital systems work best when users can confident and informed.

5. Pilot, Learn, Scale

Begin with a single line or process. Measure results, tweak strategies, and scale gradually across the factory.

Digital Maturity is No Longer Optional

In the world of aerospace machining, where quality, traceability, and speed are critical, digital maturity has moved from a "nice-to-have" to a "must-have". The Digital Maturity Index provides manufacturers with a tangible, actionable roadmap to transform their operations - from manual drudgery to smart, predictive excellence.

Indian aerospace suppliers who invest in their digital evolution today will be tomorrow's preferred partners for global OEMs. They will deliver quality, ensure compliance without chaos, and achieve operational excellence at scale.

For aerospace machining companies, the future isn't just digital - it's digitally mature.

Ready to elevate your aerospace manufacturing with digital transformation? Contact us today to begin your journey toward higher digital maturity.